Did you ever think about ecology in the printing industry? What is ecological printing? How do we produce paper? Is the recycled paper really so eco-friendly?

Our magazine is an object produced with many environmental concerns. When selecting paper, we paid attention to sustainability of the materials we use and looked for those which are natural, renewable, recyclable and biodegradable. That’s why we only choose paper with a number of environmental certificates and labels. We also spoke with Paweł Kunowski – the paper and print Advisor from Europapier.

Dobromila Blaszczyk: Rarely do people even realize that “ordinary” paper contains only 3% cellulosic fibres (i.e. wood pulp), the remaining materials are the substances used for binding, coloring, coating etc. Is there really so little paper in the actual paper?

There are multiple variations of paper – the so called “synthetic paper” contains no cellulose whatsoever.

Paweł Kunowski: Cellulose is merely the processed fibre component of wood. Paramount to the papermaking process is the pulp consisting of water, pigments, adhesives and other materials. The initial paltry amount of cellulosic fibres in the liquid solution increases after the water is drained and then evaporated. Every kind of paper has a unique percent composition: coated, uncoated, recycled etc.

D.B.: What’s the definition of recycled paper? Is it really eco-friendly?

P.K.: Recycled paper is made from the wastepaper, meaning previously processed fibres. Unfortunately, wastepaper contains the mixture of dyes, primers, stickies and pigments. Therefore, it needs to be properly cleaned prior to the manufacturing process, for instance bleached (otherwise the paper will be naturally greyish) or reinforced with stronger glue in case of short fibres. Environmental benefits of this kind of paper derive from the recycling component. However, the final product is in fact far less eco-friendly than one might presume. Its harmful effect on the environment exceeds the one inflicted in the production of virgin paper from raw materials (Munken) certified by the Nordic Swan Ecolabel, which signifies the company’s minimum environmental impact with regard to paper production, use and waste. In other words, eco-paper reduces the environmental impact not only at the stage of production, but also processing and ultimate disposal. Recycled paper does not fulfil all these criteria.

D.B.: What should we pay attention to while choosing the eco-friendly paper?

P.K.: Certificates, for sure – FSC, PEFC, Nordic Swan, Ecolabel, Blue Angel, EMAS etc. Detailed information on sustainability is always posted on every paper manufacturer’s website.

D.B.: Certification criteria often pertain to sustainability and forest management. What type of trees can be used in paper production? Is every kind of wood suitable for papermaking?

P.K.: Paper is produced from various types of wood rejected by the furniture and construction industry, including deciduous and coniferous trees. Every cellulose has different qualities. FSC Certification provides assurance that a given product comes from responsibly managed forests.

D.B.: Apart from forest exploitation, we should also focus on water consumption. In our last conversation, you mentioned the water waste treatment plant operating by the paper mill delivering the product to our new storage unit (Munken). The purified water flows into the nearby salmon farm, then the fjord.

P.K.: Of course, Artic paper mill is furnished with a state-of-the-art treatment plant that returns the pristine water back to nature. In fact, the facility merely “borrows” these resources – 93% of water used in paper production is drained, the remaining 7% is removed in the steaming process. In the case of Munken, 3-4 m3 of water is used to manufacture a ton of paper. Biological waste meets all the criteria indispensable for dispersing it on the adjacent fields, which cultivates natural ecosystems. The clean water is used for breeding trout and salmon, then flows into the fjord.

D.B.: What is more, they even used to conduct experiments in the self-contained production process to preserve the condensed water…

P.K.: Unfortunately, these plans have never been implemented permanently in the mill. Closed water system encourages rapid algae formation whose removal with the essential, yet toxic chemicals, is hardly environmentally friendly.

D.B.: What about the traditional paper?

P.K.: To produce a ton of offset paper, you need approximately 10m3 of water. A pulp mixture of 0.2-1.5% fibre is processed in the paper machine; the rest is just water. Presumably, circa 15m3 of water is required for making a ton of “the usual” paper for copy machines or everyday use, compared to the abovementioned 3-4 m3 demonstrated by Munken.

D.B.: Perhaps a viable solution would be a paper production process that substitutes the cellulosic fibres with natural resources, such as fruit and vegetable waste which would otherwise be tossed or used to make food for animals.

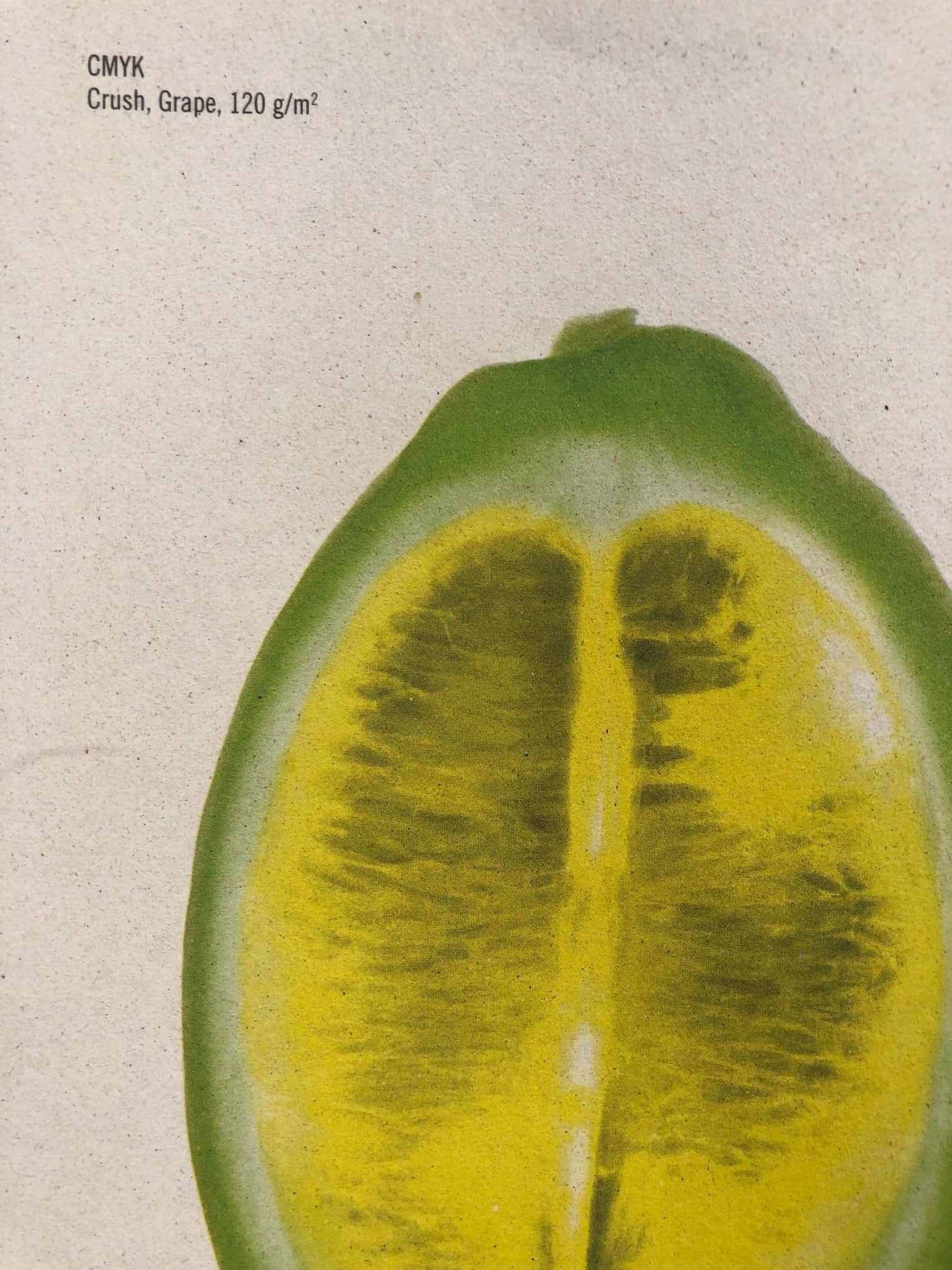

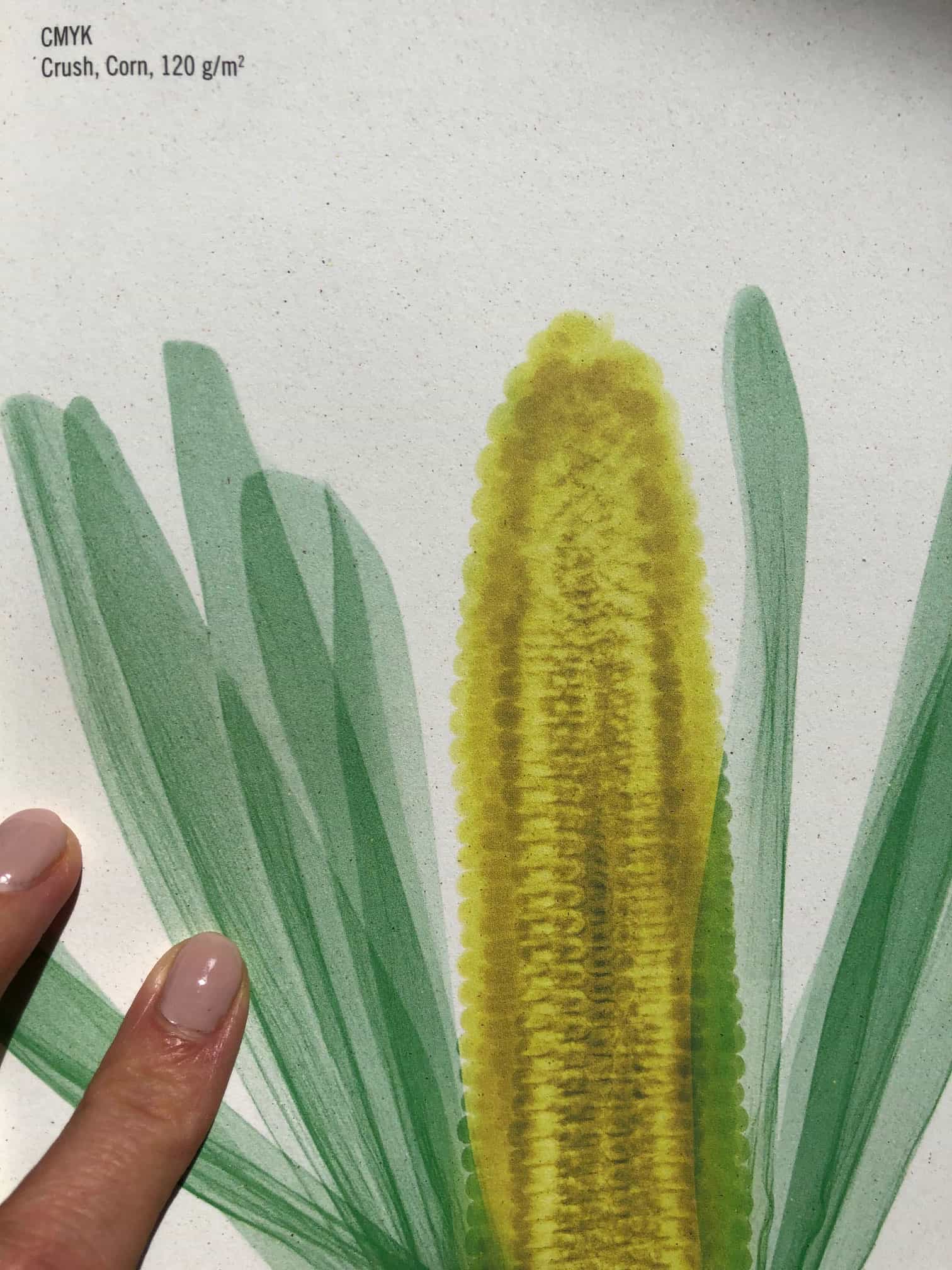

P.K.: Definitely, a portion of cellulose can surely be replaced by fully biodegradable organic materials. For instance, Crush contains 15% dried plant fibres. These are natural products, so you could say that our company uses 15% less cellulose to make paper.

D.B.: Another significant issue we failed to mention so far is the price component. Why are the recycled and eco papers more expensive than “the usual” paper?

P.K.: The price reflects an incredibly complex and painstaking production process that employs a broad spectrum of certified cellulose. Paper mills abide by the sets of guidelines, certification requirements, as well as innovative solutions implemented to reduce heat and power consumption.

D.B.: Who issues these certificates? Is it a group of independent experts / scientists?

P.K.: Different certificates are provided by different bodies. Let us take FSC as an example – the members of this international organization founded in 1994 include the entities dealing with the rights of communities, indigenous peoples, environmental protection, forests’ certification, forests’ owners and managers, wood and paper mills, retail networks, as well as private individuals interested in sustainable forestry. International organizations with the FSC membership are for instance Greenpeace, WWF, Sierra Club and Friends of the Earth. The Working Committee FSC – Poland oversees the certification process at the national level, the member companies include Arctic Paper Polska, Barlinek, Castorama Polska, IKEA and the accredited NEPcon Sp. z o.o. The social branch is composed of e.g. NSZZ Solidarność (the Independent and Self-Governing Trade Union Solidarność) and Związek Leśników Polskich w Rzeczypospolitej Polskiej (Forestry Association of the Republic of Poland), while the environmental branch is represented by Liga Ochrony Przyrody (League for Nature Conservation), WWF Polska, Ogólnopolskie Towarzystwo Ochrony Ptaków (Polish Society for Birds’ Protection) etc.

In addition, certification schemes implemented in FSC aim to verify the compliance of all procedures. The accredited certification bodies are eligible to assess whether a given firm’s operations abide by the FSC standards. Accreditation Services International (ASI), which presides over the certification scheme in FSC, conducts annual audits in the accredited bodies’ offices, as well as on random locations. What is more, the so-called certifiers must act in accordance with the ISO 65 norms.

D.B.: What should we do then with the exorbitant amounts of paper we throw away every single day? We’re talking daily newspapers, packaging, cards, documents etc. If we intend to lead an eco-friendly lifestyle, should we just rely on waste sorting or carry the wastepaper to the collection point? If you have a fireplace, it’s supposedly worth investing in the paper briquette machine to press old magazines. Is there any other way?

P.K.: It’s a huge dilemma, to be honest. Segregation in a collection point might not be your best option considering potentially harmful substances within the wastepaper. Needless to say, electronic solutions spring to mind; Fun fact, tough – one hour spent on the internet releases three times more carbon emission than a production of one kilogram of paper. You could choose the following:

– throw it away: not recommended, it takes much longer for any newspaper to decompose in a landfill,

– recycle: try to reappropriate the waste you’ve produced, use brown paper for packaging etc. As consumers, we’re sadly attracted to shiny new things, hence greyish eco products are considered far from alluring (and successful),

– compost: selected types of paper, e.g. Munken or Crush, are perfect for it,

– burn: interesting option, but beware of the add-ons, such as primers, sheets and pigments, which have at least some environmental impact. If you opt for briquettes, then throw only the paper made from natural resources into the flames. Otherwise, you run the risk of poisoning the environment – chalky paper, LWCs, synthetics, cartons and processed packaging are to be avoided.

Thank you for the conversation.

Dear Reader, we are pleased to inform you that the latest issue Contemporary Lynx Magazine dedicated to the Environmental Activism in Art was printed on the following papers mentioned above: MUNKEN LYNX, CRUSH FAVINI CORN and KIWI, as well as Ensocoat. Enjoy your reading!